Foss – Grain & Oilseed Analyzer – ProFoss™ Range

Real-time, accurate production monitoring for animal feed using in-line feed analysis directly in the process line. It is robust enough to withstand tough production environments and gives instant results for optimized production and profitability.

Improve quality and reduce cost with true in-line oilseed analysis. Get full control of moisture, protein and oil with measurements every 2-3 seconds directly in your production line. Detect trends early to identify when product is out of spec and make immediate corrections.

Key Features

Trend Analysis

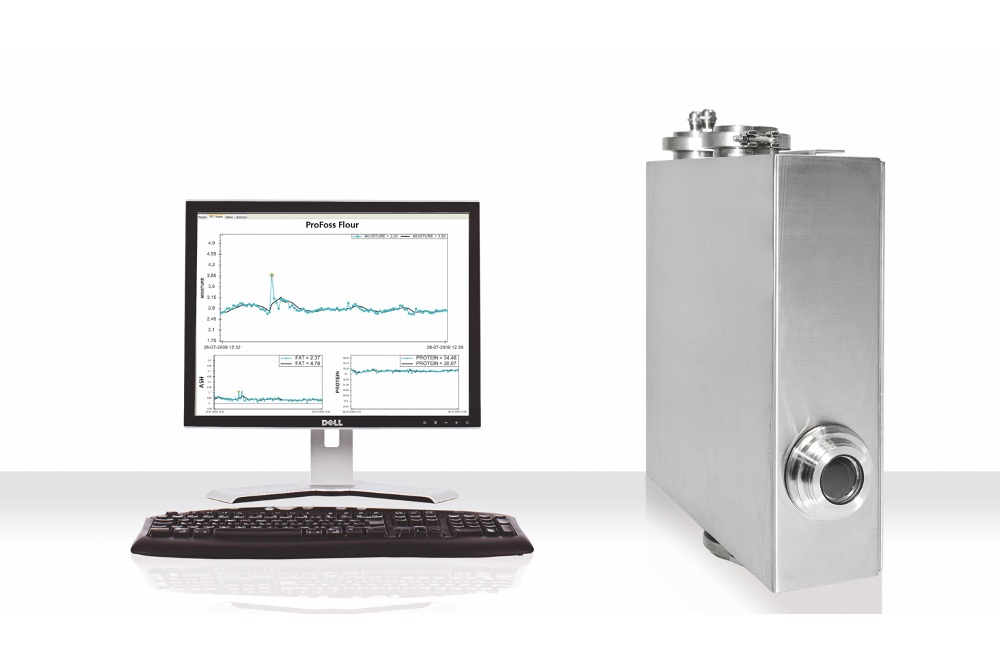

ProFoss™ allows you to do direct measurements in the process line, thereby effectively avoiding sampling errors and sample preparation errors. The results are shown in an intuitive graphical display, making it easy to spot variations. Because ProFoss™ is measuring every few seconds it gives a reliable picture of what is going on in the process.

Easy Integration

ProFoss™ can easily be connected to your LIMS or ERP system.

Dedicated Sample Interface

- Windows interface connected directly to the pipe

- True in-line – no bypass – reduces waste and sampling errors

- No moving parts

- No carry-over effects between analyses

- IP 65

FossConnect™

FossConnect™ is a centralized networking management solution for ProFoss™ that helps you reduce your production costs and secure the quality of your products. With FossConnect™, you can manage, configure and monitor your instruments remotely from any internet-enabled computer and safeguard your data for whenever you need it.

Technical Specifications

| ProFoss™ for feed | ProFoss™ for flour and whole grain | ProFoss™ for oilseed meals | |

|---|---|---|---|

| Analysis time | Real time: Average analysis time per result 2 – 3 seconds | 5 – 50 ms / integration time; Average time per result 3 – 15 seconds | 5 – 50 ms / integration time; Average time per result 3 – 15 seconds |

| Measurement mode | Reflection | Reflection | Reflection |

| Wavelength range | 1100 – 1650 nm | 1100 – 1650 nm | 1100 – 1650 nm |

| Detector | InGaAs Diode array | InGaAs Diode array | InGaAs Diode array |

| Spectral dispersion | 1.1 nm / pixel | 1.1 nm / pixel | 1.1 nm / pixel |

| Light source lifetime | – | Dual lamp system MTBF = 17500 h | Dual lamp system MTBF = 17500 h |

| Software package | ISIscan NOVA™ for instrument control | ISIscan™ for instrument control; ISIcal™ for calibration development | ISIscan™ for instrument control; ISIcal™ for calibration development |

| Wavelength accuracy | < 0.5 nm | 0.5 nm | 0.5 nm |

| Wavelength precision | < 0.02 nm | < 0.02 nm | < 0.02 nm |

| Wavelength stability | < 0.01 nm/ °C | < 0.01 nm/°C | < 0.01 nm/°C |

| Noise | < 60 micro AU | < 60 micro AU | < 60 micro AU |

| Random Vibrations | 0.4 Grms | 0.4 grms at 10 – 150 Hz according to IEC 60068-2-64 0.4 grms at 10 – 1250 Hz according to FOSS internal standard (more information available on request) | 0.4 grms at 10 – 150 Hz according to IEC 60068-2-64 0.4 grms at 10 – 1250 Hz according to FOSS internal standard (more information available on request) |

| Temperature | Max 150 °C (302 °F) | -5 – 40°C (23 – 104°F). With purge -5 – 65°C (23 – 149°F) | -5 – 40°C (23 – 104°F). With purge -5 – 65°C (23 – 149°F) |

| Installation in ATEX zone | – | 0 – 40°C (32 – 104°F). With purge 0 – 65°C (32 – 149°F) | 0 – 40°C (32 – 104°F). With purge 0 – 65°C (32 – 149°F) |

| Purge air | Cooling air Flow rate minimum 5 l/min, >99.9 % water free, >99.9 % free of oil and fine | Flow rate minimum 5 l/min, > 99.9% water free, > 99.9% free of oil and fine particles down to 0.3μm | Flow rate minimum 5 l/min, > 99.9% water free, > 99.9% free of oil and fine particles down to 0.3μm |

| Ambient humidity | < 90% RH | 10 – 90 % relative | 10 – 90 % relative |

| Dimensions (W × H × D) | 42 × 42 × 13.5 cm (16.5 × 16.5 × 5.3 inches) + brackets to hold the unit | 42 × 42 × 13.5 cm (16.5 × 16.5 × 5.3 inches) + brackets to hold the unit | 42 × 42 × 13.5 cm (16.5 × 16.5 × 5.3 inches) + brackets to hold the unit |

| Weight | 25 kg / 55 lbs | 25 kg / 55 lbs | 25 kg / 55 lbs |

| Cabinet | 1.5 mm (lid 2.5mm) Stainless Steel EN 1.4301 (SS2333) | 1.5 mm (lid 2.5mm) Stainless Steel EN 1.4301 (SS2333) | 1.5 mm (lid 2.5mm) Stainless Steel EN 1.4301 (SS2333) |

| Protection | – | IP69K 1) according to IEC 60529 and DIN 40050 part 9, NT ELEC 023 | IP69K 1) according to IEC 60529 and DIN 40050 part 9, NT ELEC 023 |

| Communication | KEPServerEX (Ethernet, Analogue Profibus/Profinet) to PLC/SCADA; FossManager™ | OPC, Profibus, Profinet, 4-20 mA | OPC, Profibus, Profinet, 4-20 mA |

| Power supply | 1 phase, 100-240 VAC (max ±10 % of the rated voltage), max. 40 VA, 50 – 60 Hx | 1 phase, 100-240 VAC (max ±10 % of the rated voltage), max. 40 VA, 50 – 60 Hx | 1 phase, 100-240 VAC (max ±10 % of the rated voltage), max. 40 VA, 50 – 60 Hx |

Available Models

Gaining More Control of Soymeal Crushing

How to Raise Quality in Flour Milling

More Products

FOSS creates end-to-end solutions that secure and improve food quality. From raw material to finished product. Our analysis instruments refine…