Foss – Digestor™ 2508 and 2520

Free up time for other tasks with fully automated digestion. Convenient, safe and flexible operation backed by data and application logging.

Digestor™ 2508 and 2520

The 2508 and 2520 Digestor™ series for flexible and safe Kjeldahl digestion with different levels of automation.

| Digestor 2508 | Digestor 2520 | ||

|---|---|---|---|

| Tubepositions | 8 tubes | 20 tubes | |

| Automation | Automated | Automated | |

| Tube volume | **100 ml, 250 ml and 400 ml | 250 ml and 400 ml | |

| Options | Rack system / Auto lift / Exhaust / Scrubber | Rack system / Auto lift / Exhaust / Scrubber | |

| Power supply | 200-240 V, 50-60 Hz | 200-240 V, 50-60 Hz | |

| Power consumption | 1100 W | 2300 W | |

| W x D x H (mm) | 300 × 440 × 140 | 300 × 600 × 140 | |

| Water supply | EM 2508 Exhaust Manifold: 3 -5 l/min for 5 minutes, then 1 l/min | EM 2520 Exhaust Manifold: 10 – 12 l/min for 5 minutes, then 3-5 l/min | |

| Weight net | 10 kg | 18 kg | |

| * Time and temperature** Adapter required | |||

Key Features

- 2501 Scrubber Unit: For Kjeldahl digestions the 2501 Scrubber Unit should always be considered for safe and efficient neutralisation of corrosive gases. This replaces the water aspirator, supplied as standard.

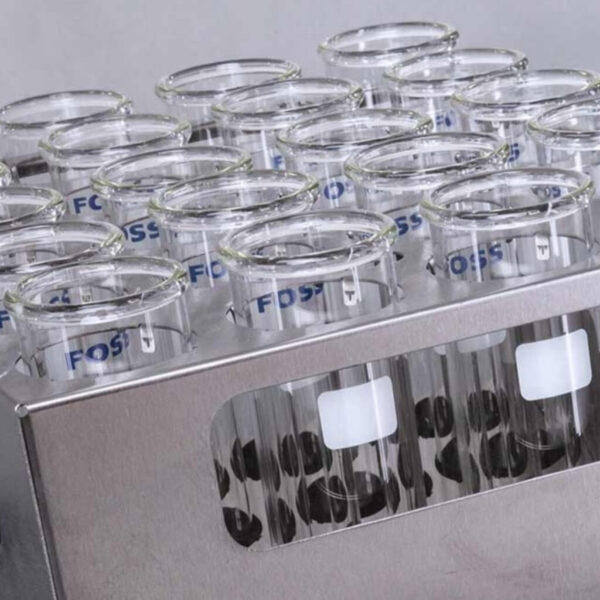

- Exhaust manifolds: All models are delivered with a tube rack with integrated heat shields. They should always be combined with a matching exhaust manifold designed for each Digestion Unit facilitating fume removal, or reflux head and test tubes – 100 ml, 250 ml or 400 ml volume.

- Software: Auto systems have memory for up to 127 FOSS Applications and 127 User Applications. There are currently more than 80 FOSS applications in the CD Library supplied.

Technical Specifications

| Performance data at 230 V | |

|---|---|

| Temperature range | Ambient – 440°C |

| Temperature setting repeatability | 1°C |

| Temperature stability at 100°C | ± 2°C |

| Temperature stability at 400°C | ± 1°C |

| Heating up time 20 to 400°Cat 230 V | Digestor 2508: ~35 min Digestor 2520: ~40 min |

| Digestion application memory | Up to 254 |

| Digestion steps per application | Up to 23 |

| Lift connection | Yes, full control |

| Scrubber | Digestor 2508/2520: Yes, full control |

| Ventilation requirement | Exhaust system and Fume hood |

Learn How Automated Kjeltec Provides More Consistent Lab Results

More Products

FOSS creates end-to-end solutions that secure and improve food quality. From raw material to finished product. Our analysis instruments refine…